-

Call: +919930660616

-

Mail: sales@smvkengineering.com

-

Plot No. W-2B, Near Post Office, Anand Nagar MIDC, Ambernath(East), Thane, Maharashtra-421506

All Type of Insulation Material Suppliers

- Home

- All Type of Insulation Material Suppliers

Products

- All Type Pipe fittings & Valves suppliers

- All Type of MS Steel Suppliers

- Fabrication of SS / MS Reactor & Pressure Vessels

- Fabrication of SS / MS Tankss

- Fabrication of SS / MS Condensers & Heat Exchangers

- Fabrication of SS / MS Sheet metal

- Fabrication of Chimney

- Fabrication of Ducting

- All Type of Insulation material suppliers

- Manufacturing of Gratings

Looking

for a Fabrication & Erection Of Pipelines, Piping Fabrication

Service and

much more.

Contact Us

All Type of Insulation Material Suppliers

Do you want to get high-quality Insulating Materials at an affordable price? You arrive at the right place.

This information will explain you more about insulation materials and their applications.

Continue reading further below.

What is Insulation Material?

Insulation is a material that helps protect people and things from heat or cold. The most common type of insulation is thermal insulation. There are several types of heat-conductive materials, each with advantages and disadvantages.

This product is a tough, fire-resistant, and durable insulation material used for many different purposes. It is used to insulate pipes and other parts of industrial equipment. It is also used in building construction to keep the inside and outside of the building cool.

When insulation is placed between two surfaces, it traps heat or cold and helps to keep things at a consistent temperature. This material is typically made from glass fiber, rock wool, or cellulose.

Insulation material is a product used for insulating an object from heat and cold, typically used in industry. It is made from a durable, flexible material coated with a thermosetting resin that has a long life and can withstand high temperatures. This type of insulation is used in various industries, such as power plants, petroleum refineries, and oil drilling sites.

The Top 7 Thermal Insulation Materials

Currently, a variety of inexpensive thermal insulating materials are available. Each material's cost, R-value, use, and environmental implications differ. Thermal insulation in your home minimizes both winter and summer heat losses, resulting in more stable inside temperatures. Furthermore, adding insulation to your home can lower your electricity bills by 50%! The seven most prevalent insulating materials used in residential and commercial applications are listed below.

- Glasswool Insulation

- Earthwool Insulation

- Polyester Insulation

- Rockwool Insulation

- Reflective Foil Insulation

- Insulation rigid boards (EPS & XPS)

- Spray Foam Insulation

1. Glasswool Insulation

In residential, commercial, and industrial contexts, glass wool insulation is the most often used insulating material. Glass wool insulation, sometimes described as fiberglass insulation, is made up of up to 80% recycled glass. Glass is melted in a furnace and spun into fibers. The glass filaments of glass wool insulation create millions of tiny air spaces. The R-value of glasswool insulation ranges from R1.5 for walls to R6.0 for ceiling applications. Glasswool insulation is relatively affordable compared to other insulating materials. Glasswool thermal insulation items include Earthwool Insulation, Fletcher Pink Batts, and Bradford thermal insulation.

Glasswool features and benefits:

- Superior thermal efficiency for all-year comfort.

- Non-combustible.

- Lowers energy bills by conserving energy.

- Simple to use and install.

- Lightweight, adaptable, and durable.

2. Earthwool Insulation

Glasswool insulation is a common type of insulation. However, Earthwool insulation is a product produced by smvk. So what sets Earthwool insulation apart from other types of glasswool insulation? Earthwool insulation is created with ECOSE advanced technologies, a bio-based binder that is sustainable and free of formaldehyde. Traditional petrol-based chemicals are not employed. Earthwool is a well-known thermal insulation material used in residential, commercial, and industrial settings. It is available as a wall, ceiling, floor, and acoustical product.

Earthwool features and benefits:

3. Polyester Insulation

Polyester comprises at least 50 percent recycled PET plastic, such as beverage bottles, which would otherwise end up in a landfill. Polyester fibers are joined using heat rather than binder chemicals. As a result, polyester has a rigid yet flexible structure. Polyester is a well-known thermal insulation material because it includes no inhaling particles and is an excellent choice for persons with asthma or severe dust allergies. Furthermore, since no protective clothing is required, the polyester fabric is pleasant to feel and itch-free, making it a tremendous Homemade material for your renovation or refit project.

Polyester thermal insulation products are much more costly than glasswool thermal insulation materials. However, it is utilized in similar applications as glass wool. It has both commercial and residential buildings. Timer-frame studs are pre-cut to fit in walls, ceilings, underfloor, and mid-floor joist spacings. Polyester insulation goods include Bradford Polymax, Autex Greenstuff Polyester, and the Autex acoustic line.

Polyester features and benefits:

- Produced using recycled materials.

- The material is reusable in and of itself.

- Non-allergenic particles let you breathe a little easier.

- Touchable, non-toxic, and non-irritant.

- Non-flammable.

- The warranty period of 50 years.

4. Rockwool Insulation

Basalt rock is used to make rock wool insulation. Rockwool is made by melting the stone and spinning it at high temperatures to make fibers molded into insulation batteries or rolls. There is no binder resin utilized in this process. Rockwool insulation has good fire ratings since it is non-combustible, doesn't conduct heat, and can withstand temperatures above 1000°C. The ability of Rockwool to insulate operates by trapping air between the strands, restricting heat transfer. The cost of Rockwool insulation is three times that of glasswool insulation. Rockwool also offers high R-values, as well as acoustic and fire standards. Although Rockwool is suitable for commercial and residential situations, it is most commonly used to build walls between tenancies.

Features and advantages of Rockwool:

- Extremely long-lasting.

- Water contact has no negative impact on performance.

- Fire Protection.

- Non-combustible.

- Excellent acoustic ratings.

- Excellent thermal efficiency.

- Warranty for ten years.

5. Reflective Foil Insulation

This insulator has a reflective aluminum surface (or similar material). As a result, many internal professionals can start working before installing the tile and shell, increasing on-site workflow efficiency. On its own, reflective foil insulation has a low R-value of about R1.0. However, substantially greater R-values can be obtained when adequately constructed with a dry air gap (sealed chamber with no air movement).

Dead air space generates an additional R-value, so the more significant the overall R-value, the quieter the air space. Reflective foil, utilized in both residential and commercial industries, enhances the thermal insulation value of your home by reflecting heat that enters the structure.

Features and benefits of reflective foil:

- Cost-effective.

- It is thin and light, making it simple to use and fit

- Because it is not affected by moisture, it can be utilized as a vapor barrier.

- Non-biodegradable and non-flammable.

- It is safe and straightforward to install with less safety equipment because it is non-toxic and non-carcinogenic.

- In hot climes, it keeps buildings cool and is particularly effective.

6. Insulation rigid boards (EPS & XPS)

Many insulating materials, such as SMVK, are engineered to achieve high R-values while remaining thin. Thermal insulation boards help to keep indoor temperatures consistent by minimizing heat transfer in the cold and warmth gain in the summer. Insulation boards will have either a closed cell or an open cell structure.

Closed cell constructions are stiffer and robust and serve as an excellent waterproof membrane to keep wetness from entering your home. A closed-cell insulation board is extruded polystyrene, often known as XPS insulation. On the other hand, the open cell structure is lighter and slightly firmer, and the thermal insulation layer incorporates air holes. An open-cell insulation sheet is an extended polystyrene, often called EPS insulation.

Insulation sheets are an efficient thermal insulation material for both residential and commercial constructions, and they are used for a variety of purposes, including:

- Roofs, walls, ceilings,and cathedrals.

- Residential subflooring installation.

- The lining of an industrial factory.

7. Spray Foam Insulation

Spray foam often costs much more than alternative types of insulation. It is usually installed with a blasting machine by a certified professional installation. As a result, the overall cost is frequently higher. Spray foam, on the other hand, is more successful at sealing air leaks, decreasing water leaks, and preventing mold formation. Check-ups are also less regular because the insulation is less likely to be ruined. Foam spray does have a lifespan of roughly 50 years if kept dry.

Spray foams are divided into two categories, similar to stiff panels: open-cell foams and closed-cell foams. Open-cell spray foams are thicker and spongier due to the air that flows through the cells, offering superior sound-dampening effects. However, closed-cell foam insulation costs more than open-cell insulating foam. On the other hand, a closed cell has a more durable and solid structure that stops air and water from seeping inside your home. As a result, foam spray works well for retrofit projects and is an excellent thermal insulator for apartment complexes.

Features and advantages of spray foam insulation:

- Lower your energy bills.

- Reduces air draughts in your home by providing an airtight seal.

- Prevents mold growth.

- The long life expectancy of up to 50 years.

- Environmentally friendly product.

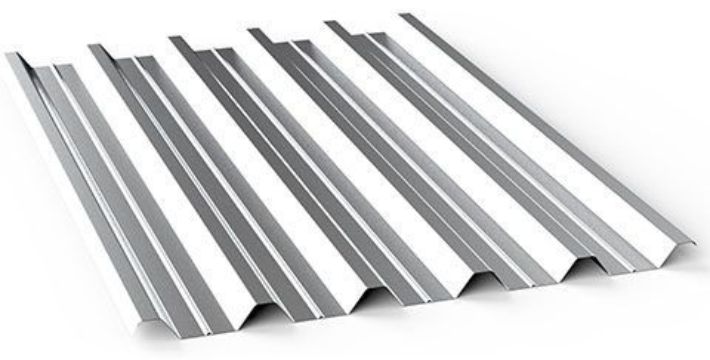

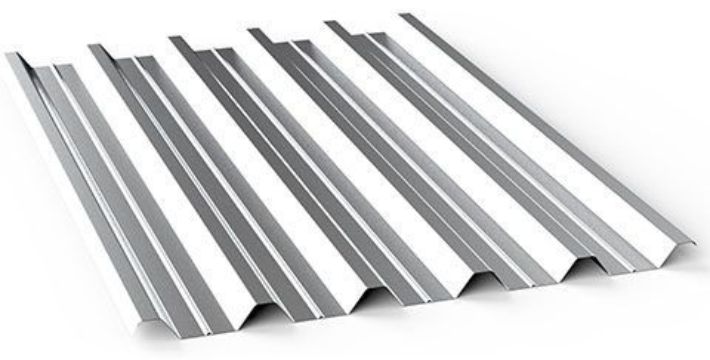

What Is G.I. Sheet?

The shorthand for galvanized metal sheet is G.I. sheet. It is a zinc-coated steel sheet to avoid corrosion and prolong the life span. In addition, there are galvanized flat plates and contour sheets on the market. Galvanized steel sheets are classified into two types: hot-dip galvanized sheets and electro-galvanized plates. Because of its excellent corrosion resistance and pleasing look, it is a cost-effective option in buildings, automobiles, furnishings, household goods, boats, and other applications. Please keep reading for more details.

G.I. Sheet Thickness

The galvanized metal sheet is a common building material. G.I. sheet layers varying between 0.2 to 4mm are available from SMVK. The most typical thickness ranges from 0.2 to 1.5mm. You can choose your choice based on your needs. For example, decking sheets are commonly 0.8-1.2 mm thick. Use G.I. sheets with a diameter of 0.45-0.75 mm if you intend to construct CGI ceiling sheets. The chart for G.I. sheet sizes is presented below.

What Exactly Is Galvanized Iron Sheet?

The galvanized iron sheet is a construction material composed of mild steel with a zinc coating on the surface. Galvanizing is a popular anti-rust method that is both cheap and effective. It has a smooth, shiny surface with enormous spangles, regular spangles, little spangles, or no.

Galvanized sheet weight calculator: Weight=7.85*length (m)*width (m)*thickness (mm)+ weight of zinc layer. (Density of steel = 7.85 g/cm3)

Here is an example: If you have a length of 2.3 meters, a width of 0.95 meters, and a thickness of 0.35 millimeters. If the thickness of the zinc coating is 100 g/m2. As a result, the steel sheet weighs about 6,22 kg. In addition, the breadth here refers to the total width of the corrugated galvanized sheet.

Types of Galvanized Iron Sheet

G.I. sheets come in a variety of styles. Because of the various galvanizing techniques, there is hot-dip galvanized sheets and electro-galvanized steel sheets.

Hot Dipped Galvanized Sheet: The primary result of the continuous galvanizing procedure is a hot-dipped galvanized sheet. In other words, a constant bath of molten zinc heated to 450 degrees is used to coat the steel coil. This process produces a thick layer of zinc, which crystallizes into crystalline zinc spangles. The thick zinc covering thoroughly covers the exposed steel. As a result, under standard settings, its service life surpasses 30 years. By the way, the zinc layer of SMVK is Z40-275 g/m2.

Electro-Galvanized Sheet: Cold-rolled steel is a common lightweight material in electro-galvanized sheets. After that, the electro-galvanized sheet is electro-deposited with zinc coating. The constant electrolytic coating procedure produces a thin, uniform zinc layer. As a result, the electro-galvanized steel has a smoother appearance. However, it lacks the corrosion resistance of hot-dip galvanized steel.

Plain & Corrugated Galvanized Sheets: Plain galvanized iron sheets and corrugated galvanized iron sheets come in a variety of forms (CGI). The G.I. sheets are available in widths ranging from 1 to 12 m, thicknesses varying from 0.12-2.5 mm, and widths ranging from 600-1,500 mm. Plain GI sheets are suitable for the back panels of home appliances and furniture. They can also be further processed for other uses, such as door panels, fences, etc. In addition, corrugated sheets are frequently used in roofing and wall panels. You can choose according to your intended use.

G.I. Sheet Uses

Galvanized steel sheet is a multipurpose product with numerous applications.

- Construction Business: Roof sheets, wallboard, fences, gutters, roofing grills, balcony panels, glass panels, warehouses, rolling gates, doors, pipelines, and other items.

- Automotive Industry: Outer shells of cars and tractors, bicycle chassis, internal panels, bottom sheets, containers, highway fencing, ship bulkheads, agricultural machines, and so on.

- Light Industry: cooling devices, washing appliances, freezers, household appliances, water heaters, chimneys, cooking utensils, and other similar items

- Furniture Industry: wardrobes, tables, bedside cabinets, file cabinets, bookshelves, and other applications.

- Additional applications include outdoor billboards, hoppers, nuts, bolts, nails, solar projects, buckets, fermentation tanks, etc.

Advantages of Galvanized Steel Sheets

1. Excellent Corrosion Resistance

The zinc coating entirely preserves the metal surface, even in grooves and angles, and provides excellent corrosion resistance. Life expectancy in most rural areas is greater than 30 years. Is the galvanized steel sheet going to rust? Of course, yes. It will, however, be somewhat slow.

2. Low Cost

Galvanizing is a low-cost protective coating for steel. Galvanized steel costs less than galvalume steel. It also requires less maintenance. In the long run, it is also highly cost-effective.

3. Smooth Appearance

The galvanized sheet has a smooth, gleaming, silver-white surface. As a result, it is used without the addition of any additional paints or decorations. Also, the galvanized coating adheres exceptionally well, making it an ideal material for PPGI steel.

4. Wide Applications

It is widely utilized in various industries, such as vehicles, electronic devices, construction materials, etc. Because of the multiple applications, it is also a fantastic financial project. Therefore, we also offer discounts for bulk orders. For further information, please get in touch with us.

What Is the Manufacturing Process for Galvanized Steel Sheets?

- Pre-treatment (e.g., polishing with an alkaline) to remove grease and other contaminants from the surface of the base steel.

- Drying to boost the temperatures and eliminate moisture from the top of iron parts before galvanizing to prevent an explosion.

- galvanization Once annealing, the zinc coating is securely deposited by dipping in a melted zinc bath at 445-455°C or electroplating. After a while, the steel's surface is coated with either a zinc-iron alloy coating or a zinc layer.

- Cooling to form a stable zinc coating on the surface of the steel.

- Surface grinding to remove remaining zinc and zinc oxide compounds.

- Quality assurance.

- Cut coils into sheets to sell.

"What is G.I. sheet?" may help you better comprehend galvanized steel. If you have any additional queries, please get in touch with us. SMVK is a trusted provider of galvanized steel sheets in India.

Aluminum Sheet

An aluminum sheet is described as a cold-rolled material that is more than 0.2mm thick but less than 6mm thick. Alloy Buying Guide: The various available alloys are divided into work-hardening and heat-treatable. Aluminum sheet metal is a versatile metal sheet that is used in a variety of applications and industries. It possesses chemical and structural qualities that distinguish it from other metal sheet choices.

What is Aluminum Sheet Metal?

Aluminum sheet metal is manufactured by pressing and rolling aluminum material under high pressure. Aluminum sheets are usually lightweight but strong enough to be helpful in a wide range of industrial applications. In addition, the aluminum metal sheet is highly versatile and simple to manufacture, making it one of the most popular metal sheets on the market.

Aluminum sheet metal can also be coated and have different surface finishes.

Before acquiring an aluminum metal sheet, it is critical to understand the key characteristics of this metal.

The following are a few of the major significant advantages of aluminum metal sheets:

Lightweight

The aluminum sheet is around one-third the weight of a steel sheet, making it one of the lightest metal sheets on the market. It makes the sheet easier to handle and helps reduce the weight of structures, which is essential for cost.

Corrosion Resistance

Corrosion is a concern in a variety of environments and industries. Aluminum is one of those materials that does not rust readily. Corrosion in aluminum sheets requires extremely intense corrosive forces, with some alloys having more excellent corrosive resistance than others.

Strength

Although aluminum sheet metal is lightweight, it is also quite strong. Therefore, it is beneficial in various industrial applications due to its strength and lightweight nature. In addition, it is a long-lasting, cost-effective shape for dealing with forces and stresses generated in multiple structural applications.

Formability

Aluminum sheet meal has a relatively low melting point. As a result, it may be easily shaped into various shapes when heated to a given temperature.

Usable for Sensitive Applications

Aluminum alloy sheet is excellent for food and chemical packaging. Because it does not react well with many other materials, there is no danger that the aluminum sheet may negatively affect the meal.

Reflectivity

The reflectivity of aluminum sheet metal, which reflects light and heat away from its surface, makes it perfect for lighting applications.

Fireproof

Aluminum sheet metals are resilient to burning when exposed to fire, with just a tiny layer of sheet metal affected. In addition, aluminum sheet metal does not emit hazardous gas when subjected to high temperatures.

Recyclable

The aluminum sheet is also recyclable; this is one of the most well-known and widely used properties of aluminum sheets. Many aluminum metals that are currently in use have been recycled.

Offered in Multiple Thickness

Aluminum sheet metal is available in various thicknesses and sizes and multiple dimensions.

Affordably Priced

Although aluminum metal sheet has numerous advantages, it is relatively inexpensive compared to other metal options. However, its low cost does not reduce its quality or utility in many applications. Therefore, aluminum sheet metal is the best option for many businesses looking for a lightweight yet flexible and robust metal.

Applicable for a Range of Industrial Uses

The use of aluminum sheets will frequently depend on the metal's thickness of choice. Thinner sheets of aluminum are typically used in small-scale applications. This is where the topic of sheet metal gauges comes into play. The sheet metal gauge tells you how thick it is and whether it suits your application.

As a highly adaptable metal, the aluminum sheet is employed in many applications across many sectors—the uses for this type of aluminum range from small and sensitive to a colossal scale.

This metal is found practically anywhere because it is helpful in many sectors. It is extensively used in the food and beverage industries for cookware and packaging. The aluminum sheet is also commonly utilized in the bodywork and framing of automobiles. This metal sheet is also widely used in the construction and building business for sidings, drainage, and other goods.

Aluminum metal sheets are also suitable for producing metal nameplates and other related goods. For example, aluminum sheets are commonly used for creating vehicle number plates because they are inexpensive, have high corrosion resistance, are lightweight, and require little maintenance.

Why Choose SMVK Enginnering & Fabrication

SMVK Enginnering & Fabrication is the most reputable supplier of Insulation Materials for your business. We provide all types of Insulation Materials at the most competitive prices, including Rockwool, Ceramicool, Glass wool, Nitrile Insulation, Thermocol, Aluminium Sheet, G.I. Sheet and more. All Around India, including Mumbai and Maharashtra. We offer top-quality Insulation Materials that can satisfy the demands of our clients. Are you looking for affordable Insulation materials for your Applications or Projects? Then SMVK Enginnering & Fabrication is the company for you.